Graphene : The Carbon Allotrope

What is Graphene? Before that what is Carbon Fibre?

A thread made up of carbon is called carbon fibre, graphene is an allotrope of carbon and hence threads (fibres) made up of graphene are called graphene fibres.

The isolation of graphene led to the discovery of a whole family of 2D materials, including hexagonal boron nitride and molybdenum disulphide. These can be combined with graphene to create new 'designer materials' to produce applications originally limited to science fiction.

Combinations of

these 2D materials are called heterostructures - tiny towers with different

layers of different materials. Any combination is possible, which means new

materials can be built from the ground up on an atomic level to create

materials tailored to exact functions.

MANUFACTURING PROCESS

Methane, a carbon-rich gaseous compound with which we humans are very familiar, can be reacted with copper at high temperatures to produce graphene. Simply heat the copper to about 1,000 degrees Celsius and expose it to the methane gas. Layers of graphene will form on the copper’s surface from the plentiful carbon atoms in the methane gas, a process called Chemical Vapour Deposition (CVD).

There are two big problems with this method:-

1) It takes a long time to make even a little graphene, and

2)The quality of the graphene produced is not very good.

David Boyd at California Institute of Technology, along with his research collaborators, has found a way to improve on the CVD approach so that it will work with lower temperatures and produce higher quality graphene. They, too, use copper and methane, but they add a bit of nitrogen to improve the layering of the graphene on the copper. In this method, energy still needs to be added, but not nearly as much. The reaction goes forward at a “mere” 420 degrees. The global industry has considerable experience with CVD, so it should be possible to eventually automate the process on a large scale; the goal is to produce centimetres or even meters of high-quality graphene at a time.

Other methods are used for large scale manufacturing such as chemical deposition, but research continues to be carried out to scale up new capabilities of producing larger quantities of graphene. Graphene is a disruptive technology; one that could open up new markets and even replace existing technologies or materials. It is when graphene is used both to improve an existing material and in a transformational capacity that its true potential can be realised. Combining all of graphene's amazing properties could create an impact of the scale last seen with the Industrial Revolution. The vast number of products, processes and industries for which graphene could create a significant impact all stems from its amazing properties. No other material has the breadth of superlatives that graphene boasts, making it ideal for countless applications.

·

It can even be stronger than Diamond, yet incredibly lightweight and flexible.

·

It is electrically and thermally

conductive but also transparent. It is also the Most Impermeable Material.

· It is the world's first 2D material and is one million times thinner than the diameter of a single human hair.

Now let us explore various and vast applications of graphene.

Biomedical

Graphene's unique properties allow for ground-breaking biomedical applications. Targeted drug delivery; improved brain penetration; DIY health-testing kits and 'smart' implants. Graphene-based materials including pristine graphene sheets, few-layer graphene flakes, and graphene oxide offer a variety of unique, versatile and tunable properties that can be creatively utilized for biomedical applications. Graphene applications in biomedicine are numerous and can be classified into several main areas: transport (delivery) systems, sensors, tissue engineering and biological agents (for example antimicrobials).

Graphene is a material with a huge amount of outstanding qualities; strength, flexibility, lightweight and conductivity. One of the simplest and most effective ways of harnessing the potential of graphene is to combine it with existing products - so-called composite materials. The impact of graphene-based composites are set to reverberate throughout countless industries, enhancing performance and increasing application possibilities.

Rust-free Future

By combining graphene with paint, a

unique graphene coating is formed which could signal the end of the

deterioration of ships and cars through rust.

Weatherproofing and Packaging

The same technique could also be applied to brick and stone, to weatherproof houses, or even to food packaging to stop the transfer of water and oxygen molecules which causes food to go off. Further benefits come from incorporating graphene-based composites in major components in industries such as construction, transport or aerospace.

Graphene for Sport

Sporting goods are often the first to

take upon new materials development which has already been the case with the

successful graphene-enhanced tennis racket from Head. Graphene-based composites

and coatings could be further involved in enhancing sports equipment in skiing,

cycling, and even Formula 1 soon.

A graphene-based composite aircraft wing could drastically decrease weight, reduce the detrimental effects of lightning strike damage and increase fuel efficiency and range. This could result in the world's lightest, strongest, safest, greenest plane.

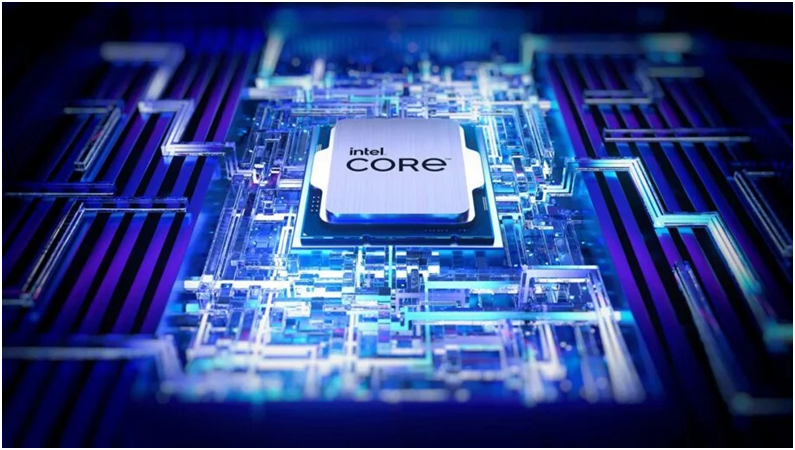

Graphene Electronics

Graphene can be used as a coating to improve current touch screens for phones and tablets. It can also be used to make the circuitry for our computers, making them incredibly fast. Graphene could see a smartphone which you could wear on your wrist or a tablet you could roll up like a newspaper. Indium-tin oxide is currently used for touch screens as it conducts well but it is brittle.

Graphene's unique properties of thinness and conductivity have led to global research into its applications as a semiconductor. At just one atom thick and with the ability to conduct electricity at room temperature, graphene semiconductors could replace existing technology for computer chips. Research has already shown that graphene chips are much faster than existing ones made from silicon.

Graphene in Batteries

Graphene could dramatically increase the lifespan of a traditional lithium-ion battery, meaning devices can be charged quicker - and hold more power for longer. Batteries could be so flexible and light that they could be stitched into clothing. Or into the body. For soldiers, who carry up to 16 lbs of battery at one time, the impact of this could be huge. Carrying less weight, and using batteries that can be recharged by body heat or the sun would allow them to stay out in the field for longer.

Graphene Filtration

Graphene oxide membranes are capable of forming a perfect barrier when dealing with liquids and gasses. They can effectively separate the organic solvent from water and remove water from a gas mixture to an exceptional level. They have even been proved to stop helium, the hardest gas to block.

Comments

Post a Comment