Electro-less Plating

Electro-less Plating

|

| https://www.sharrettsplating.com/coatings/electroless-nickel |

In this blog, we will take a look to the

Questions:

●

What is Electroless Plating?

●

What makes it different from

Electro-Plating?

●

What factors affect

the Plating Quality?

●

What are its Advantages and

Disadvantages?

● What are the Applications

Electro-less

Plating:

Electro-less Plating is a class of industrial

chemical processes that create metal coating on various materials by

autocatalytic chemical reduction of metal cations in liquid bath. It is also

known as Chemical Plating or Autocatalytic Plating

The story of Electro-less plating begins in 1946

at the 34th Annual AES Meeting, when Abner Brenner and Grace Riddell of the

National Bureau of Standards disclose results of their studies on experimental Nickel electroplating baths. They had

attempted to prevent undesirable oxidation of bath constituents at the inert

anode by making additions of reducing agents to the bath. As luck would have

it, one of the reducing agents explored was sodium hypophosphite. Surprisingly, the amount of nickel deposited exceeded

the amount theoretically limited by Faraday's law.

They soon found out that nickel deposition

occurred even when no external current

was applied. It was clearly seen that metal deposition was achieved by chemical

reduction but, uniquely, the nickel deposit was itself catalytic for continued reduction. The process was thus

described as autocatalytic chemical reduction of metal ions to form a metal deposit.

What makes

it different from Electro-Plating?

●

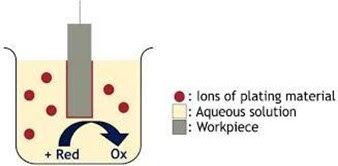

Electro-Plating involves passing of

electric current from the bath and the substrate for reduction of Metal cations

(in the solution) to occur. i.e. transfer of electrons occur due to potential

difference applied.

●

While, in Electro-less Plating, the

Reduction of Metal cations (from the solution) occur purely by means of

Chemical Reduction. i.e. electrons are provided by the oxidation of a Reducing

Agent.

The general reaction of Electro-less Plating

is

Mz+(aq) + Xz-(aq)

where M represents the metal, Xz- the reducing agent, and Z its

oxidized byproducts

|

| https://interplex.com/wp-content/uploads/Technical-Bulletin-Electroplating-Electroless-Plating-Differences-Benefits.pdf |

In order for the metal to be deposited as

a uniform solid coating on the intended surface, rather than a precipitate

through the solution, the reaction must require a catalyst that is either the

substrate itself or is applied to it beforehand. In fact, the reaction must be

autocatalytic, so that it can continue after the substrate has been coated by

the metal.

Other

Materials which can be used for Electro-less Plating:

●

Nickel-Phosphorous as alloy

●

Nickel-Gold as alloy

●

Nickel-Boron as alloy

● Palladium as alloy

● Copper

Electro-less nickel plating uses nickel salts as the metal cation source and either hypophosphite (or a borohydride-like compound) as the Reducer. A byproduct of the reaction is elemental phosphorus (or boron) which is incorporated in the coating. Tollens' reagent is a classical example of electro-less silver plating. For other metals like gold and copper, the reducing agent is typically a low-molecular-weight aldehyde.

What factors affect plating quality?

Plating

Quality is affected by several factors out of which majority should be taken

care of during Surface Finishing.

Surface preparation:

Rough, badly machined surfaces with uneven metal surfaces, burrs or cold shuts

cannot be effectively plated.

Cleaning: The surface should free form oils,

dirt and soaps formed by saponification of oils by alkaline cleaners.

Control of the plating baths: Temperature, pH, nickel ion concentration and hypophosphite concentration all need to be effectively managed to ensure high quality, consistent plating finish.

Advantages of Electroless Plating:

Electro-less plating has an upper hand over electrolytic plating.

They are

1. Uniformity

With Electro-less plating, the coating deposits on the surface more

evenly, but the thickness of the coating is quite thin as compared to Electrolytic

plating. This even coating can be justified by the fact that deciding factor in

how thick the coating applies to the surface depends on the base’s contact with

the solution, every surface has the same amount of metal coated to it.

|

| https://maf.com/2016/11/22/electroless-nickel-plating-explained/ |

2. Durability

A layer of nickel-phosphorous plated onto an object with electroless plating provides superior strength for the item it covers. .

3. No Conductivity Required

Electro-less plating can be done on Non-Conducting Surfaces. Thus, Plastics can be uniformly coated.

Disadvantages of Electro-less Plating:

Even though Electro-less plating has many benefits, this method will not be suitable for all uses. Only your project parameters will help you determine the answer.

Limited Bath Life

In Electro-less plating, metals ions are supplied by the bath instead of a metal piece, eventually the bath will run out of metal ions and so needs to be changed.

This will require Regularly Monitoring the liquid and adding solution as required which will in turn increases the cost and complexity of autocatalytic plating.

Applications:

Electro-less Plating find its application in many industrial

sectors to achieve durable, corrosion resistant nickel coating on their

products.

Few of them are mentioned below:

● Automotive Industry:

Engine components that are exposed to elevated temperatures and

regular use require a durable exterior which can be achieved from electro-less

nickel plating.

● Manufacturing:

Molds,

machine parts, dies and more are protected from corrosion and wear by the

application of Electro-less nickel coating in any manufacturing setting.

●

Aerospace Industry:

Same as the automotive industry, the aerospace sector requires

heat- and rust-resistant parts in the engine and throughout the aircraft.

Nickel plating is one of the way to attain the durability needed for these

components.

● Petrochemical Industry:

Petrochemical plants regularly need replacement valves, pipes, plugs and more. A long-lasting nickel coating withstands the heavy friction these parts may experience while protecting the components against corrosion. Thus, increases their life-span.

Blog Credit:

Praful Sunil Kadam (TY Metallurgy and Material Science, 111911029)

(Team Meta Monday)

References:

https://monroeengineering.com/blog/electroplating-vs-electroless-plating-whats-the-difference/

https://www.sharrettsplating.com/blog/electroless-autocatalytic-vs-electrolytic-plating/

https://www.google.com/url?sa=i&url=https%3A%2F%2Fmaf.com%2F2016%2F11%2F22%2Felectroless-nickel-plating-explained%2F&psig=AOvVaw1dJOAaenck98XCYG6tUwaT&ust=1641212590610000&source=images&cd=vfe&ved=0CAsQjRxqFwoTCNjwxMWHk_UCFQAAAAAdAAAAABAD

https://en.wikipedia.org/wiki/Electroless_plating

https://encrypted-tbn0.gstatic.com/images?q=tbn:ANd9GcSpPEtI9I02H7XQv7B2-k-fhXq9UUVtcEcIlw&usqp=CAU

NASF SURFACE TECHNOLOGY WHITE PAPERS

(Historical Highlights of Electroless Plating by

Charles R. Shipley, Jr.)

Comments

Post a Comment