Seaweed: The future of sustainable future

SEAWEED : The Future of Sustainable Packaging

You must have heard about edible water pouches!

These transparent water pouches can be directly eaten with its packaging material. The

packaging material is completely edible.

Lets take a look at speciality of these seaweed based

packaging.

From what is this packaging made?

This packaging is made from polysaccharides of marine macro algae

called seaweed. Seaweed are heterogeneous plants that live in either marine or

brackish water environments. It is one of several groups of multicellular algae: red, green and brown.

Brown Seaweed

14,073 Brown Seaweed Stock Photos and

Images - 123RF

How is the packaging developed?

Seaweeds are used globally to make biodegradable and edible

packaging materials. Polysaccharides such as agar, carrageenan and alginate are

extracted from seaweeds. These have excellent film forming properties. Then the

raw material is fermented without any chemical processing. The yeast residue

can then be converted into animal feed. The packaging is made edible without

the use of any adulterants or preservatives. However, seaweed films have high

water sensitivity, which indicates a poor water resistance due to the

hydrophilic nature of seaweeds extracts. Therefore, biopolymer films produced

from seaweed biomass are improved for desired characteristics to be used as a

packaging material.

Visakhapatnam centre of CIFT develops edible seaweed film that can replace plastic in food packaging - Frontline (thehindu.com)

Speciality in this packaging:

These bio-based polymer is non-toxic to nature. This

packaging degrades in just few days to few weeks in natural environment

depending upon plastic and environmental conditions.

Normally, microbes

use enzymes to slowly ‘eat’ biodegradable plastic. In the case of this new

material, however, the enzymes are built into the plastic itself. When the

plastic is thrown away, and the humidity and temperature are right, the enzymes

are activated. The enzymes break down the plastic more completely than

microbe-produced enzymes. This is because they go from one polymer chain to the

next, rather than breaking down the polymer in random areas. As a result, no

microplastic remains following decomposition. This could help overcome the

current environmental challenges associated with materials like oxo-degradable

plastics, which have been shown to decompose but to leave microplastic

fragments as they do, polluting soils and water.

Because the new

material will break down into monomers, it could also be recycled rather than

composted. And the embedded enzymes also break down the plastic more completely

than microbe-produced enzymes. Considering the edible bioplastics the

polysaccharides gets digested by bacteria present in human body.

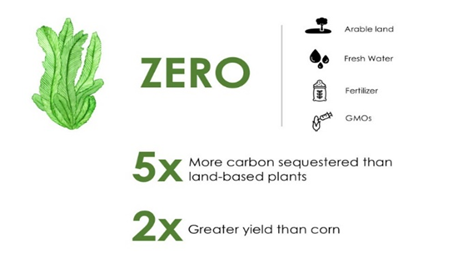

Why Seaweed ?

Seaweed shows a promising future in the packaging industry

for several reasons:

·

Seaweed proliferates: As a raw

material, seaweed proves simple to cultivate, growing up to 3 meters a day. The entire crop is ready to harvest within a

little over a month, making the grow-time entirely manageable.

·

Seaweed is easily accessible: It

grows on every coastline. It’s also simple to extract from the shore or harvest

a crop.

·

Seaweed is inexpensive: Unlike other

crops, it doesn’t require fertilizers or freshwater, making it comparatively

cheap to produce.

·

Seaweed products decompose: Unlike

their plastic packaging counterparts, seaweed is biodegradable. Single-use

straws, or containers for restaurants, are biodegradable in four to six weeks. Some plastic bottles take

hundreds of years to decompose. Rather than let seaweed products disintegrate,

you can also choose to eat them.

·

Seaweed is sustainable: Scientists

collect the material to ferment it and create packaging. This process requires no chemical distillation, unlike similar materials. The procedure’s

only effect is a yeast by-product that can be converted and fed to farm

animals.

·

Seaweeds are nutritious: Seaweeds are

rich in minerals, antioxidants and fibers. They are also rich in protein

and vitamins.

The Tuck 360 Blog | Is Seaweed the Future of Sustainable Packaging? (dartmouth.edu)

The NOW and FUTURE of seaweed based packaging:

Currently, large-scale seaweed aquaculture only occurs in

Asian countries such as China, Japan, Indonesia and Korea, due to the

continent’s high demand for seaweed food products.

Indonesia is one of the largest seaweed producers in the world,

and the leading global producer of red seaweed. Evoware, a sustainable packaging company in Jakarta has been

creating food and other product packaging derived from seaweed since 2016,

demonstrating the materials’ efficacy as a packaging alternative that is not

only biodegradable but also edible.

plastic waste.

These “ohoo”

bubbles are created by company Notpla.

London Marathon Runners Were Handed

Seaweed Pouches Instead Of Plastic Bottles (forbes.com)

With more and more companies pledging to ‘go green’ and look

for innovative ways to package their products, seaweed packaging could grow to

become a worldwide source for small-scale packaging solutions looking at its

all over benefits. In terms of the large-scale products, seaweed may not work

due to costs, labour concerns and durability as of now.

oceans are

proving an abundant source for packaging alternatives – and companies are

turning to ocean-based plant fibres to create biodegradable containers and

wrappers.

The seaweed packaging as a replacement for plastic packages

is going to impact the cleanliness of the sea because no more plastic waste

will end up in the ocean and it will protect life below water since no more

fish, plankton or any marine living creatures will eat the micro plastic. Also,

it will significantly reduce the garbage in landfills and will improve air

quality.

Seeing these benefits countries are carrying out active

researches on improving the production techniques. In a densely populated

country like India, different hazardous plastics are used rampantly due to the

need for packaging of different consumer and food products. Researchers from

NIOT (National institute of ocean technology) have now however successfully

developed and tested bioplastic films by opting environment-friendly

techniques.

Seeing the trends, the seaweed industry is expected to

increase significantly around the globe in coming 10 years.

References:

2.

Development of Seaweed Biodegradable

Nanocomposite Films Reinforced with Cellulose Nanocrystals for Food Packaging;

Hansol Doh; Clemson University, hsdoh02@gmail.com

3.

Seaweed:

the new material of our sustainable future? (greenstories.co.in)

4.

3116290121Seaweed-PPT_28012021.pdf

(ncdc.in)

5.

Development

of biodegradable plastic from Marine Seaweed (vigyanprasar.gov.in)

Comments

Post a Comment