Superalloy: The Superior Alloy

Hello and Welcome to Meta Monday.

Let us introduce you to today’s Agenda:

● What Are Superalloys? And Why are they ‘Super’?

● Types of Superalloys

● What can they be used for?

https://www.cam.ac.uk/research/news/super-superalloys-hotter-stronger-for-even-longer

Alloys

Metals are one of the primary components of everything humans

have built. Infrastructure, transport, industries, everything is built using

metals. But there are many metals each with its amazing characteristics.

So why use them just one

at a time? That’s where alloys came into the picture, a combination of elements

of the periodic table in which at least one is a metal in specific proportions

Few of the most common alloys are steel, bronze, brass,

stainless steel, all are nothing but a specific mixture of elements. Humans

felt the need to mix these metals or sustainability and resistance and luster

and cost-effectiveness.

So what are Superalloys?

Well, we all know Superman. He can fly, he is strong, he can shoot lasers from his eyes everything makes him SUPERIOR to a normal man. In the same way, Superalloys are complex, high-performance SUPERIOR alloys, which have a high tolerance of oxidizing environments (environments with plenty of O2 ) and high temperatures.

Superalloys

share two core values with COEP which are strength and Endurance.

The thing that makes superalloys superior to alloys is that they are efficient and resistant to rusting and oxidation. Also, superalloys can bear a lot of heat.

Types of Superalloys

Superalloys are

classified into three main categories:

● High strength

● High thermal resistance

● High corrosion

resistance

● Machinability

● Shape memory

● Low coefficient of

thermal expansion

● Higher melting point

compared to nickel- or iron-based alloys

● Superior hot corrosion

resistance compared to nickel- or iron-based alloys

● Higher thermal fatigue

resistance and weldability compared to nickel-based alloys

● High strength at room

temperature

● High resistance to creep, oxidation, corrosion, and wear

Of these three categories, nickel-based alloys have the widest range of applications, particularly in the aerospace industry. The essential solutes in the nickel-based alloys are aluminum (Al) and titanium, with concentrations of less than 10 wt. %

Applications of

superalloys/ What can they be used for?

Considering the amount of energy humanity uses, a 1% increase in efficiency is worth billions of dollars. The part of the power plant that limits temperature is the turbine blade.

A graph depicting how the

superalloys retain their yield strength even after being subjected to extremely

high temperatures whereas steel fails to perform as efficiently in terms of

yield strength.

https://msestudent.com/what-are-superalloys-applications-history-and-metallurgy/#a

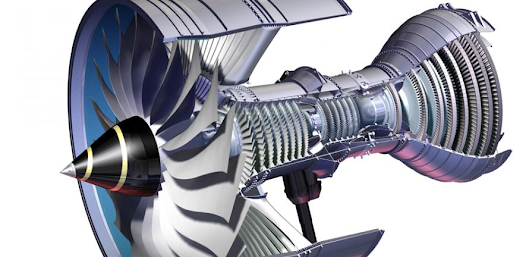

In many engineering

applications, the temperature is the

barrier that needs to be crossed. Engineers know how to make faster planes or

cars. The problem is that we don’t have materials that can survive the

temperatures necessary. Hence, the most prominent feature of superalloys that makes them

so important is their ability to withstand super high temperatures. This is why

their primary application is mostly in the turbine sector. Turbines are made

from nickel-based superalloys. The turbines are mostly used in the following

sectors

● Gas turbines (turbine

blades)

● Solar thermal power

plants (stainless steel rods containing heated water)

● Steam turbines (turbine

blades and boiler housing)

● Heat exchangers for nuclear reactor systems

Superalloys are the

pinnacle of modern metallurgy. Over a dozen elements, many of them rare, are

combined in exact quantities. Precise heat treatments are used to make them and

hence it requires better equipment to make them.

The point is: superalloys are expensive. Steel, the main competitor of superalloys, is almost a thousand times cheaper than a fully-engineered superalloy. Superalloys are also denser and hence heavier than steel, aluminum, and titanium. The cost of making superalloys in most cases outweighs the benefits of their superior properties (as the properties are superior only at high temperatures). As mentioned before, Gas turbines are the main application where the cost of superalloys is paid for by their superior properties.

RnD about New

Superalloys:

A new method of making superalloys called radiolysis is being studied. It introduces an entirely new area of research into creating alloys and superalloys through nanoparticle synthesis. Looking at the scope of nanoparticles, there would be more research coming forward about superalloys

Blog Credits:

Adityan Arumuganainar (FY Manufacturing 112113002)

Aashay Godbole (FY Mechanical 112110049)

References

https://msestudent.com/what-are-superalloys-applications-history-and-metallurgy/#a-

https://www.tms.org/superalloys/10.7449/1984/Superalloys_1984_399_419.pdf

https://www.sciencedirect.com/topics/chemistry/superalloys

NOTE:-

This blog is meant for educational purposes only. We do not own any Copyrights related to images and information, all the rights go to their respective owners. The sole purpose of this blog is to Educate, Inspire, Empower, and create awareness in the viewers. The usage is non-commercial(Not For Profit) and we do not make any money from it.

Write your feedback here:

https://forms.gle/C3ybXMPPUaJBgP618

FOLLOW US ON:-

INSTAGRAM :

https://bit.ly/coep_blogs_insta

LINKEDIN:

https://bit.ly/coep_blogs_linkedIn

YOUTUBE:-

https://bit.ly/Coep_blogs_YouTube

Comments

Post a Comment